Premium Spill Pallets Supplier in UAE

At Spill Pallet UAE, we specialize in providing high-quality spill containment solutions designed to protect your workplace. Our premium spill pallets and trays are engineered for durability and efficiency, ensuring safe storage and containment of hazardous liquids, chemicals, and oils.

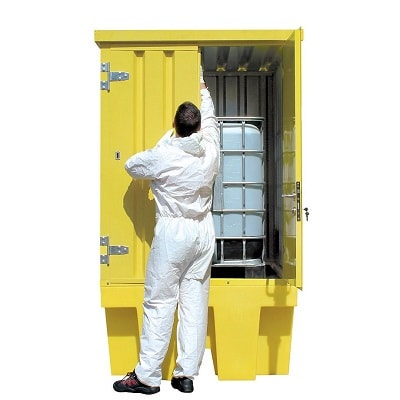

Drum bunds, spill pallets and spill containment pallets are used to safe and convenient options for storing different sized drums and containers. All these spill containment products are designed for temporary storage. These are using to improve workplace safety, housekeeping and protection of the environment. Bunded floor systems can be created by joining together low profile drum bunds. This is ideal for areas such as decanting stations, below racking systems, or storage areas where spills are likely to occur.

Drum bunds, spill pallets and spill containment pallets are used to safe and convenient options for storing different sized drums and containers. All these spill containment products are designed for temporary storage. These are using to improve workplace safety, housekeeping and protection of the environment. Bunded floor systems can be created by joining together low profile drum bunds. This is ideal for areas such as decanting stations, below racking systems, or storage areas where spills are likely to occur.

55 gallon drum containment |

Types of Secondary ContainmentSecondary containment system designed to prevent the release of hazardous substances into the environment in case of a primary containment failureContainment system are important for keeping your workplace safe. Our range of liquid spill containment generally used for oil spill containment, tank containment, diesel tank spill containment and all liquid spill containment .

Safety Storage of Oils and Chemical in Spill Containment Plastic Pallets |

Ibc bunded pallets |

Spill Tray |

Plastic Spill Trays and Drip TraysDrip trays keep contain the spills off the ground by catching leaks and drips. These large trays can also be used for bunding oil or chemical drums and larger containers. This made from 100% polythene. Catchment trays for smaller drums and cans is Robust and corrosion-free. These compact and easy to handle trays available from the sump 10L to 250L. This spill drip tray is an ideal containment unit for oils, fuels and most of chemicals.

We manufacturing and supplier of plastic spill containment products since 2011. We have a comprehensive range of products which allow our distribution partners to compete in whichever market sector they operate in. Our products are ensure high quality finished and that are compliant with the all standards. Spill Trays are durable, chemically resistant and fully recyclable. We are the UAE's leading supplier of polyethylene spill containment products and have a worldwide network.

|

Plastic drip pan |

Specialty of Our Spill Pallets and Trays

1. Custom Spill Containment Solutions:

- Custom sizes, shapes, and configurations to accommodate different container types

- Specialized designs for specific industries.

- Offering products made from materials such as polyethylene or steel..

- Knowledge of selecting the right material for different liquids.

- Ensuring all products meet safety regulations, such as EPA and OSHA

- Providing conformity compliance with local and international spill containment standards.

- Specializing in products that are built to last, offering high resistance to wear and tear, UV radiation, and extreme weather conditions.

- High-quality products that provide long-term cost-effectiveness, reducing the need for frequent replacements.

- Chemical and Petrochemical: For the safe storage and containment of hazardous chemicals, oils, and solvents.

- Automotive and Manufacturing: For containing fuel, oils, lubricants, and other liquid products.

- Food and Beverage: Ensuring safe containment of food-grade liquids.

- Pharmaceuticals and Laboratories: Offering spill pallets and trays designed for smaller containers, ensuring the safe handling of chemical.

- Agriculture: Providing spill solutions for pesticides, fertilizers, and oils.

- Integrated sump trays and drainage: To simplify spill management by collecting and removing excess liquids.

- Stackable designs: Space-saving solutions that still meet containment standards.

- Forklift-friendly pallets: For easy mobility, especially for larger operations.

- Anti-slip surfaces: For added safety in industrial environments where spills can cause accidents.

- Offering expertise in spill containment for businesses needing guidance on compliance, selecting the right products.

- Offering support with installation, maintenance, and inspections of containment systems.

Our Spill Pallets Features

1. Bright yellow color sidewalls are transient, offering convenient visual and leak detection.

2. 100% LPDE construction compatible with a board range of chemicals including acid and alkalis.

3. Our heavy duty spill pallets can be use for daily usages.

4. Molded sump catches leak/spill to help to comply with international regulations and keep your storage clean and safely.

5. Texture gratings improves traction and lifts out for easy sump access.

6.Fork Lift pockets allows easy movements from one to other directions.

7. Nestable design allows when not in use, to reduce the shipping cost and storage easy.

8. Drain plug allows to you to empty sump without removing drums or grate.

2. 100% LPDE construction compatible with a board range of chemicals including acid and alkalis.

3. Our heavy duty spill pallets can be use for daily usages.

4. Molded sump catches leak/spill to help to comply with international regulations and keep your storage clean and safely.

5. Texture gratings improves traction and lifts out for easy sump access.

6.Fork Lift pockets allows easy movements from one to other directions.

7. Nestable design allows when not in use, to reduce the shipping cost and storage easy.

8. Drain plug allows to you to empty sump without removing drums or grate.

Spill Pallets - User Manual

1. Inspect the spill pallet and grid for visual damage

2. Locate on ground level

3. Place the grid correctly

4. Check liquids stored for chemical compatibility with PE including always remove spills

5. Observe the load limit – UDL uniform distributed load. If point load we advise to place the drum or IBC on a plate to distribute the load

6. Place at a location to avoid rain filling the sump

7. NEVER move the spill pallet with drums or IBCs on. The pallet is not designed for that and a safety hazard during transport

8. Drum lifting equipment to be used when loading the drums or IBCs on to the pallet….observe slow lowering

2. Locate on ground level

3. Place the grid correctly

4. Check liquids stored for chemical compatibility with PE including always remove spills

5. Observe the load limit – UDL uniform distributed load. If point load we advise to place the drum or IBC on a plate to distribute the load

6. Place at a location to avoid rain filling the sump

7. NEVER move the spill pallet with drums or IBCs on. The pallet is not designed for that and a safety hazard during transport

8. Drum lifting equipment to be used when loading the drums or IBCs on to the pallet….observe slow lowering